How do Retractable Awnings Work?

Motorised awnings or ‘retractable awnings‘ might be extremely easy to operate, but the technology which is hidden away inside is state-of-the-art. Here’s a simple explanation of what happens when you push that button.

Motor

The motor powers an electric awning. The latest technology is is capable of driving even the largest awnings, while still being compact enough to fit neatly inside the barrel (the roller which the cover winds onto). This means all you’ll see is the awning itself (unless you choose to add heating and lighting accessories – in which case your installer will add a small receiver box onto the wall beside it).

Awning manufacturers use integrated tube motors because of their shape and built-in design. The wire which connects the motor will pass through one end of the awning, ready to be connected to your power supply by a trained electrician.

When operated the motor will wind the barrel, opening the fabric cover. The arms work because of a spring tension system or gas pistons. Many people assume they push the cover open, but the arms simply automatically follow the cover as it opens or closes. The tension from the springs or pressure of the gas ensures they open and close softly.

Arms

Most of Roché’s awnings have aluminium frameworks for strength and resilience. The standard patio awning design will have two arms, although larger models may have three or more. Each arm will comprise two main sections, connected by an elbow joint.

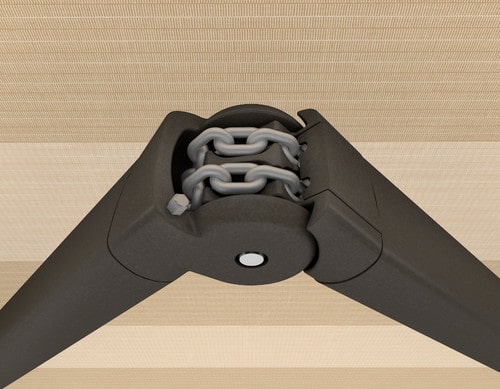

When the motor is operated the joints move in a way which is similar to a human arm extending. One or two chains connect the parts of each arm together and hold everything in place.

The first electric awnings used flyer chains similar to those on bikes. These were then upgraded to the sturdier steel link chains which are used in most awnings today. Weinor use high grade, non-rusting steel to ensure they’ll last the awning’s entire lifespan without needing to be replaced. Markilux promise to have ‘perfected power transference’ through their rounded steel link chains.

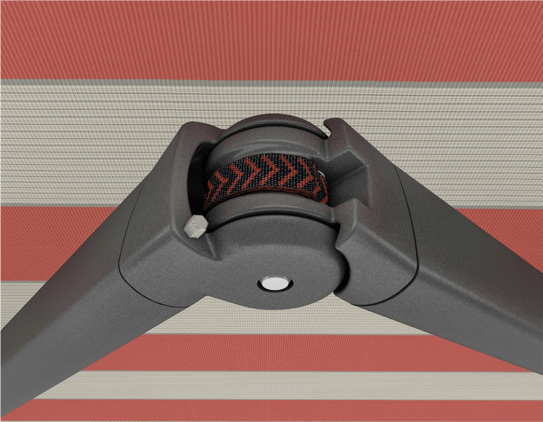

Markilux have also developed a ‘bionic tendon arm’, which is a standard feature on some models (such as the 3300 and 6000) and available as an upgrade on others. This new technology has a specially developed Kevlar mix instead of a metal chain. There’s less friction produced by extending and retracting the awning, so the only sound you’ll hear is the slight whir of the motor.

Chain Link

Bionic Tendon

Pingback: How to Fix an Electric Awning That Won’t Extend